One of the unique strengths of the MRL X-ray Facility lies in the strong research and development program aimed at developing cutting edge new capabilities in x-ray imaging and diffraction techniques. These activities include the construction of highly specialized x-ray diffraction instruments, environmental sample chambers (temperature, humidity, etc.) for in-situ structural studies, as well as developing new optics and instruments for small and wide angle x-ray scattering (SAXS/WAXS), and hard x-ray microscopy and micro-diffraction.

The research and development activities have been supported by through several NSF MRI (Major Research Instrumentation) and IMR (Instrumentation for Materials Research) development grants. In addition, the MRL facilities committee provides on-going support for the enhancement of research capabilities in the facility.

Highlights of Recent R&D Accomplishments

-

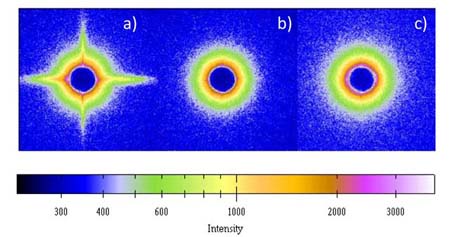

Development of Zero-Background Scatterless Hybrid Slits for Synchrotron and In-house SAXS Applications The newly developed scatterless single crystal/metal hybrid slits greatly improves performance in synchrotron and in-house SAXS instruments. The hybrid slit produces no detrimental slit scattering commonly associated with conventional metal slits, leading to a much simplified SAXS design and greater performance in terms of flux and resolution. In both synchrotron and in-house experiments, the use of the scatterless slits has led to ~3X improvement in usable photon flux at sample position without compromising resolution.

The scatterless slit has been tested by several synchrotron SAXS beamlines and is likely to become a standard feature in future SAXS design. The dramatic performance enhancement resulting from the scatterless slits technology has generated broad and rapid interest in the SAXS community and is been incorporated at many synchrotron beamlines around the world. The general scatterless design concept can be used to significantly boost the performance of a large number of existing SAXS instruments. (Supported by NSF MRI development grant DMR-0619171)

Figure - 2D SAXS background data taken at ESRF beamline D2RM showing complete elimination of slit scattering (streaks in image a) when the scatterless slits were used (b). A simplified SAXS design results in 3X more flux without compromising resolution (c ). (ESRF data courtesy Cyrille Rochas of D2AM French Beamline of ESRF and Pierre Panine of XENOCS)

-

Development of a Multilayer Bragg-Fresnel (MBFL) x-ray lens that combines diffraction and geometric focusing on a single device With the MBFL, the BFL which is deposited on the surface of the multilayer structure focuses the beam vertically while the multilayer is curved by a mechanical bender to focus x-rays horizontally. This combination eliminates the need for a second mirror in the conventional Kirkpatrick-Baez (K-B) based microprobe, reducing the complexity and cost of the optical systems. The MBFL will be particularly useful in x-ray fluorescence microscopy as well as micro-diffraction applications. The characterization of the MBFL was carried out at the European Synchrotron Radiation Facility and a 1.6 um (vertical) x 12 um (horizontal) focus was obtained from a 250 um (V) x 200 (H) um incident beam. Supported by NSF IMR development grant No. DMR-0076357. ( M. Yasa, Y. Li, C.B. Mammen, J. Als-Nielsen, J. Hoszowska, C. Mocuta and A. Freund, "Double focusing of hard x-rays using combined Multilayer and Bragg-Fresnel optics", Applied Physics Letters 84, 4744, 2004)

SEM images of circular and linear Bragg-Fresnel lenses made on GaAs

-

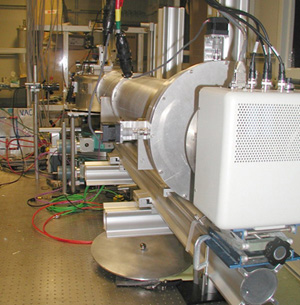

Design and construction of small and wide angle x-ray scattering (SAXS and WAXS) diffractometers Utilization of the newly developed zero-background/scatterless slits allowed to realize ultra-SAXS design with only two sets of the slits. In most cases the first set of slits is left open leading to single aperture SAXS operation, with dramatic increase of flux (~3x) at sample position. This new design architecture has been implemented on two instruments in the MRL x-ray facility: a 4-meter long ultra-SAXS and a 2-meter long intermediate SAXS instruments. Together with the custom designed WAXS instrument, these tools provide cutting-edge x-ray diffraction probing capabilities spanning length scale from 0.2 - 100 nm, suitable for nanostructure characterization of a broad range of materials.

For more details of the instrument can be found in the instrumentation page.

|

| Front and back view of the new 3.5 meter SAXS spectrometer |