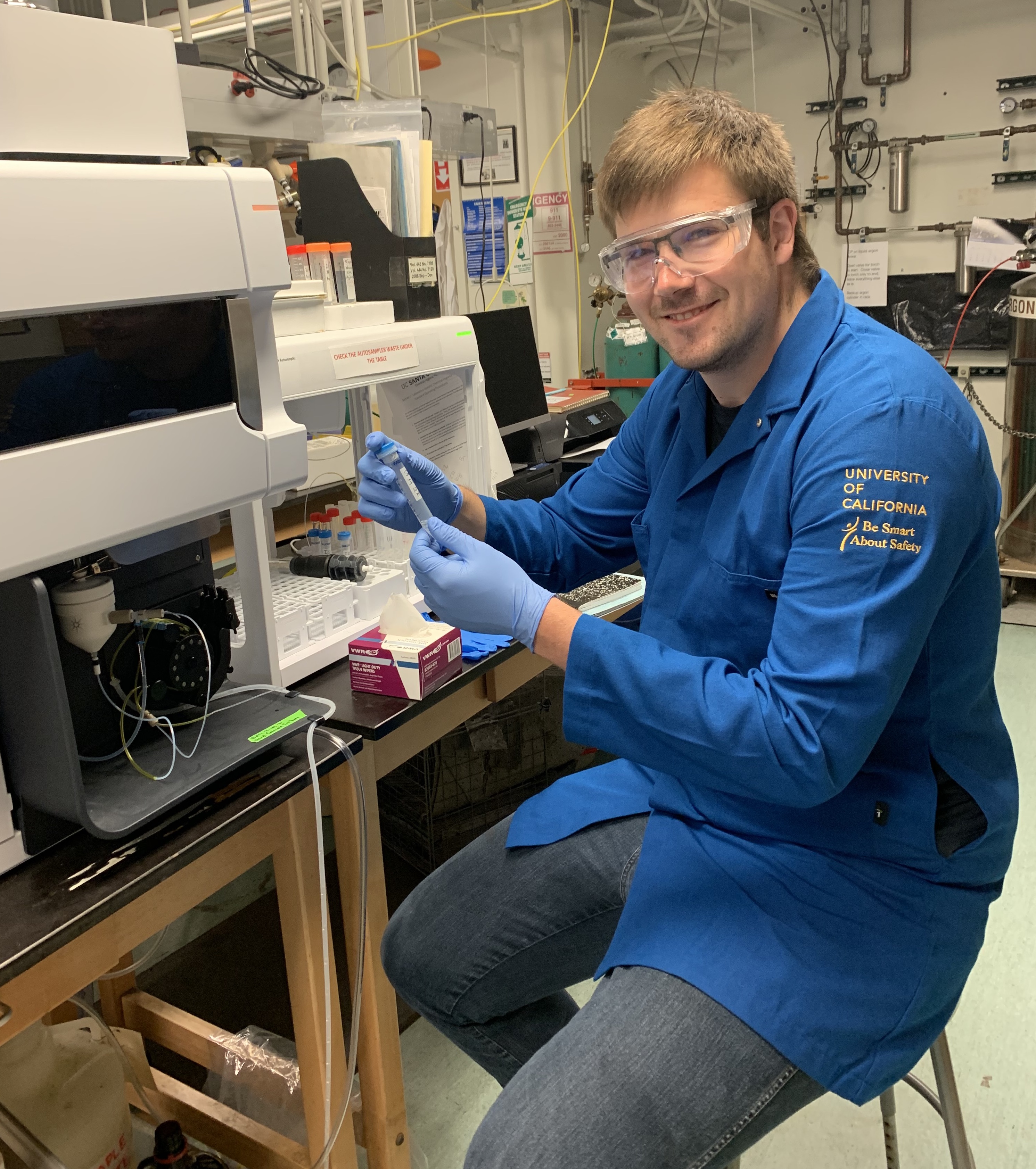

The exponential increase in the use of lithium-ion batteries has raised concerns about the accumulation of millions of tons of scarce and potentially hazardous materials, such as cobalt and LiPF6. Without proper recycling methods, the economic and environmental consequences of end-of-life batteries could be catastrophic. Hydrometallurgy has emerged as a promising recycling route in literature, involving the conversion of batteries into "black mass" through shredding and thermal treatment. Leaching steps extract valuable metals. However, the pyrolysis step, aimed at removing undesirable organics like the polymeric binder materials (typically PVDF), lacks comprehensive understanding due to the diverse compounds present in black mass samples. Little attention has been given previously to the interaction of aluminum with remaining black mass compounds. Notably, phases like LiAlO2 could potentially contribute to lithium loss during leaching if they prove insoluble. To address the challenges posed by the diverse reactants in black mass samples, this study employs model systems to investigate underlying pyrolysis reactions. The pyrolysis reactions are conducted at 650 °C using two known pure components or mixtures, and the resulting phases are qualitatively and quantitatively determined through powder diffractometry. Model validation involves comparing virgin materials with harvested counterparts from three commercially available lithium-ion batteries. To evaluate the solubility of LiAlO2 in sulfuric acid and piranha solution, inductively coupled plasma optical emission spectroscopy (ICP- OES) is employed. Initial findings indicate strong agreement between model systems and harvested samples, with disparities primarily tied to stoichiometry. Additionally, LiAlO2 exhibits limited solubility in the test solutions, and the inclusion of H2O2 does not enhance dissolution within the tested concentration range. This insight could play a crucial role in optimizing the circular economy of lithium-ion batteries, facilitating more effective recycling processes and alleviating lithium losses.