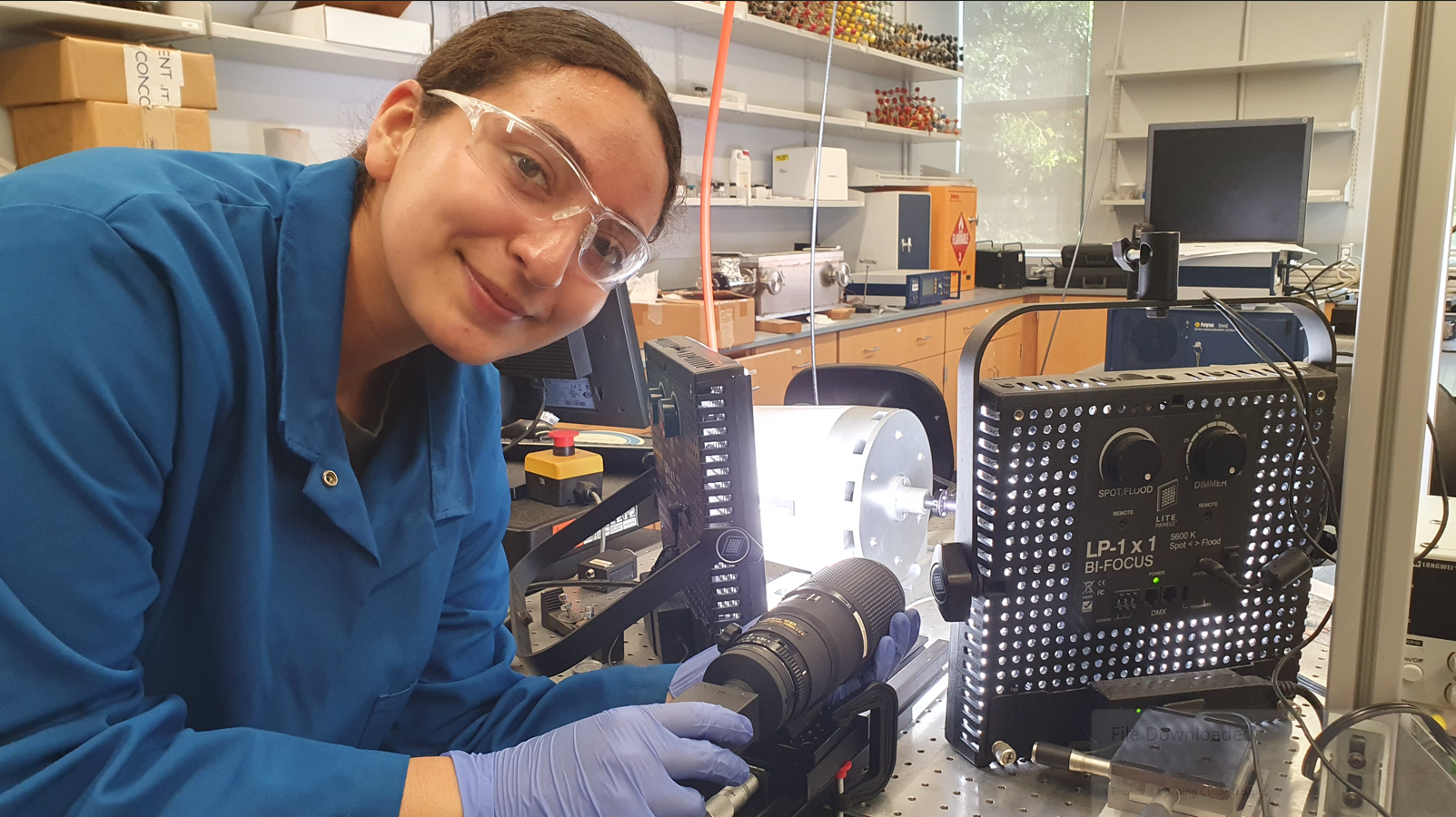

Ships at sea have limited access to replacement parts, often resulting in delays or the need to return to port for repairs. Additive manufacturing (AM) presents a possible solution by enabling ships to 3D print parts on demand. However, for this approach to be practical, a better understanding of the variability in the tensile behavior of AM-produced steel is needed. This study investigates 316L stainless steel samples, commonly used in marine applications, fabricated using laser powder bed fusion (LPBF). This process employs a laser to selectively fuse thin layers of metal powder to form complex geometries. The layer-by-layer nature of LPBF introduces variability in mechanical properties due to factors such as laser power, layer thickness, and environmental conditions. To assess this variability, digital image correlation (DIC) was employed during tensile testing to capture strain and deformation behavior up to failure. DIC showed different levels of localized strain within the samples translating into varying mechanical properties. The samples displayed inconsistent tensile behavior with differences in toughness, yield strength, ductility, and tensile strength when comparing the stress strain curves. To make LPBF viable for shipboard part replacement, process consistency must improve and to fully map variability, a larger sample size is required. This can be used to create a statistical model of variability that will allow the prediction of mechanical properties when printing ship parts.